The role of ethylene vinyl alcohol in food packaging

Ethylene vinyl alcohol, or EVOH for short, is a thermoplastic that is water-soluble (water-absorbing) and is derived from the copolymerization of ethylene and vinyl alcohol. The structure of this copolymer is resistant to chemicals and has very low permeability to oxygen, aromas, and odors.

The percentage of ethylene comonomer in the final polymer structure determines the permeability of the polymer to various gases. As the ethylene comonomer content decreases in the polymer structure, permeability to oxygen and volatile compounds in EVOH is reduced. However, to facilitate the processing of EVOH and its conversion into the final product, ethylene cannot be completely eliminated from the structure. In most grades of EVOH, the optimal percentage of ethylene is 32% and 44% molar. Although for special applications, lower or higher percentages of ethylene have also been developed.

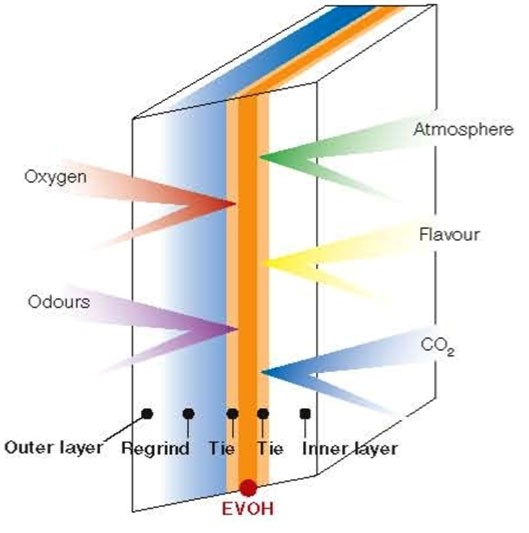

The most important application and role of ethylene vinyl alcohol in food packaging is its use in producing films, bottles, and multilayer tubes that are impermeable to oxygen in packaging industries. Today, EVOH is also used in the production of multilayer pipes for anti-corrosion installations, fuel tanks for vehicles compliant with euro 6 standards, and agricultural films (such as impermeable films against pesticides).

The presence of a very thin layer of EVOH, typically 2-15 µm, can significantly reduce and even eliminate permeability to oxygen, carbon dioxide, aromas and odors, oils, and certain organic solvents. To compare this reduction in permeability with a common polymer like low-density polyethylene (LDPE), it can be said that a piece produced with LDPE with a thickness of 10 meters has the same oxygen permeability as a 1-millimeter layer of EVOH. The table below shows the oxygen permeability of various polymers:

| Oxygen permeability at 20°C and 65% relative humidity, cm³.20µm/m²day.atm | |

| 0.41 | EVOH (32% mol ethylene) |

| 12.17 | EVOH (44% mol ethylene) |

| 32.26 | PA6 |

| 38.75 | PET |

| 458.79 | PVC |

| 5349.65 | PP |

| 10348.23 | PE |

EVOH also has very low permeability to other gases such as carbon dioxide, nitrogen, helium, and hydrogen compared to other polymers. This characteristic has led to the use of EVOH in food packaging with MAP (modified atmosphere packaging) technology. The most significant advantage of having an EVOH layer in food packaging structures is preventing the migration of mineral oils into food products. Aromatic and saturated mineral oils, known as MOAH (mineral oil aromatic hydrocarbon) and MOSH (mineral oil saturated hydrocarbon), exist in our environment.

These oils can infiltrate food packaging from various sources such as harvesting and processing machinery, transportation equipment, etc., and then enter food products through the packaging. When these oils enter the human body, various cells such as liver cells and lymph nodes are at risk, increasing the likelihood of cancer. Structures containing EVOH are impermeable to these oils and can enhance the safety and hygiene of food products.