Anti-fog additive in polymer films

In recent years, the use of polymer films has gained widespread application in greenhouse coverings and packaging of various products, including food, due to their desirable properties, transparency, and cost-effectiveness.

One of the challenges associated with the use of polymer films is the formation of fog (or dew). Fog formation occurs due to the condensation of water vapor when it comes into contact with a surface. In films used in greenhouses or for food packaging, this phenomenon is more likely due to the high humidity present.

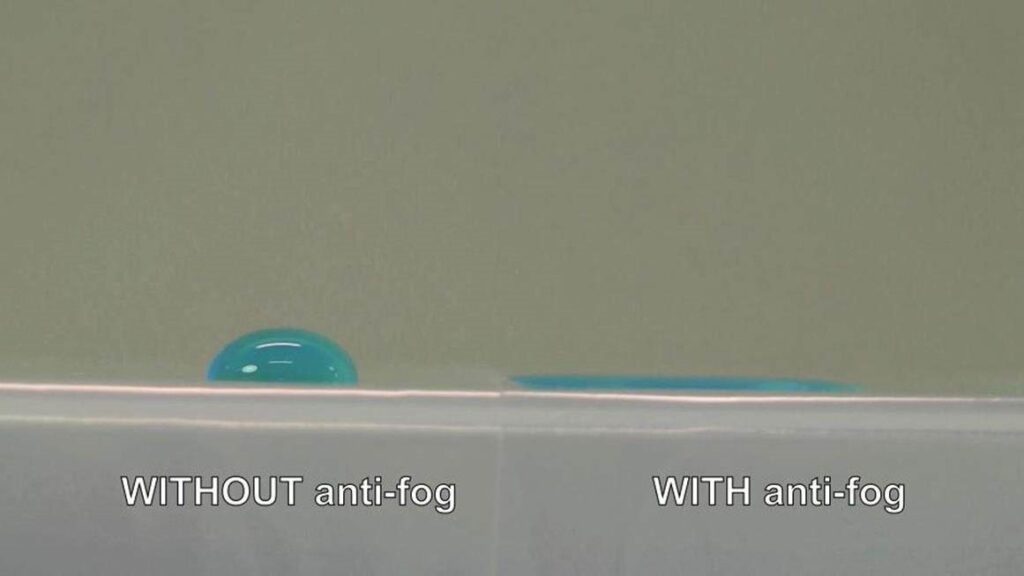

In fact, the temperature difference between the inside and outside of food packaging films or greenhouse coverings leads to the condensation of water vapor on the inner surface in the form of droplets, commonly known as fog. These droplets remain on the surface of the film due to the difference in surface tension between water and the non-polar polymer that constitutes the film.

The occurrence of fogging and the accumulation of water droplets on the film surface reduce light transmission and create a lens effect, which interferes with plant growth processes in greenhouses, damages products, and reduces clarity in food packaging.

To address this issue, manufacturers use anti-fog additives in the formulation of non-polar polymer films. The anti-fog additive migrates to the surface of the film due to its nature being incompatible with the polymer base, increasing the surface tension of the film against water. As a result, the contact angle of water droplets with the film surface decreases, causing the droplets to spread into a continuous layer on the film’s surface. This phenomenon improves the clarity and transparency of the film surface, thereby reducing the lens effect caused by the presence of water droplets.

These water layers are drained from the film’s surface through drainage channels, preventing any obstruction to light transmission and also preventing water droplets from falling onto and damaging the product.

Anti-fog additives are primarily used in polymer films in the form of masterbatches within the film’s composition and formulation. The concentration of this additive decreases over time due to its migration to the surface and its tendency to dissolve in water, resulting in a weakening of its performance.