Hazards of isocyanates in the workplace

What are isocyanates?

Isocyanates are a family of highly reactive chemical compounds. They are produced from chemical reactions in plastics and polyurethanes. Isocyanates are widely used in the manufacture of flexible and rigid foams, fibers, coatings such as paints and varnishes, and elastomers, and they are increasingly utilized in the automotive industry, body repair, and building insulation materials.

Why are isocyanates harmful?

The hazards of isocyanates in the workplace encompass numerous concerns. In fact, isocyanates are strong irritants to the mucous membranes of the eyes, gastrointestinal tract, and respiratory system. The primary concern is that respiratory and skin exposure can lead to sensitization. Deaths due to severe asthma have been reported in some sensitive individuals.

Short-term exposure to isocyanate vapors can cause irritation or burning in the eyes, nose, throat, and skin. Liquids can lead to rashes, redness, or blisters. If you work with isocyanates and experience persistent or recurrent eye irritation, nasal congestion, dryness or sore throat, cold-like symptoms, coughing, shortness of breath, wheezing, or chest tightness, you should see a doctor.

Long-term exposure can lead to a type of asthma known as isocyanate asthma. Individuals who are highly sensitive to isocyanates may react even to a few molecules of it present in the air.

Isocyanates can enter the body of workers or laminate operators through both the mouth and nose. If a worker has become sensitized to these chemicals, exposure may trigger an asthma attack. During an asthma attack, the airways may become narrowed, inflamed, and filled with mucus. In rare cases, these attacks can be fatal.

Polyurethane laminate adhesive

Who should be concerned about isocyanates?

Workers involved in plastic production or using polyurethane coatings may be at risk of exposure and should be aware of the hazards associated with isocyanates. Plastics release isocyanates into the air during production. The use of polyurethane products such as spray foam insulation, varnishes, paints, and coatings releases isocyanates. Workers in the following industries are at higher risk:

- Automotive and body painting

- Spray foam insulation manufacturing

- Industrial coatings

- Production of bedding, furniture, clothing, household items, electronics, rubber, and packaging

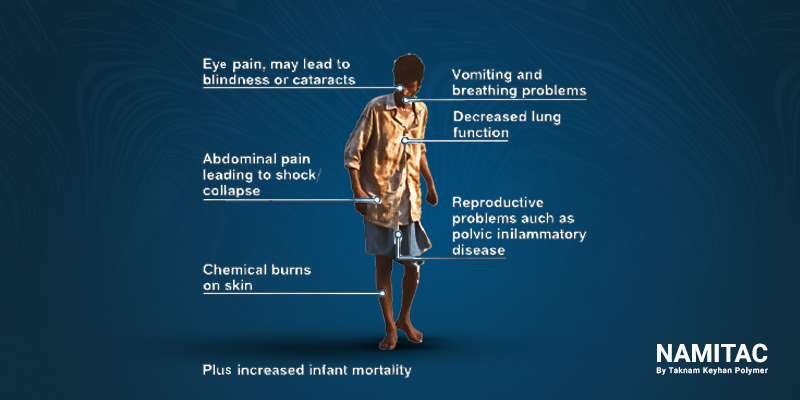

Health effects

While not all isocyanate products are hazardous, toluene diisocyanate (TDI) is considered the most toxic among them. The following details the hazards of isocyanates in the workplace in a specialized manner.

TDI irritates all living tissues it comes into contact with. TDI vapors, released when mixing two chemical compounds, may be inhaled or breathed in. Inhaling such vapors can cause severe irritation and burning of the mucous membranes of the eyes and respiratory system. Breathing these vapors can lead to nausea, vomiting, abdominal pain, and respiratory problems. Additionally, skin contact can result in rashes commonly referred to as contact dermatitis. The national institute for occupational safety and health (NIOSH) has identified TDI as a potential carcinogen (in animals).

Exposure to TDI causes serious problems in the upper respiratory system, which includes the nose, throat, esophagus, and lungs. TDI can also lead to acute irritation, chronic irritation, and sensitization of the lungs and throat. Acute irritation feels like a burn inside the nose, throat, or lungs. The throat and lungs can be damaged by TDI to such an extent that the body loses its ability to defend against infections. Such acute irritation may cause the lungs to fill with fluid. In turn, this condition can worsen infections.

Chronic irritation involves gradual changes in the body such as reduced lung capacity and leads to increased sensitivity to upper respiratory infections like chronic bronchitis. Furthermore, since lung capacity may decrease and the heart may work slower, the risk of cardiovascular or heart-related problems increases.

When a worker becomes sensitized to TDI (develops an allergy), exposure may trigger a severe allergic reaction (such as occupational asthma). In turn, this medical condition could potentially be fatal. Between two (2) to fifteen (15) out of every 100 individuals may become sensitized to TDI. Depending on the high dose, an individual/worker may become sensitized upon first contact; however, sensitization typically develops after repeated exposure.

Plus when a worker becomes sensitized, any level of exposure to TDI can trigger an allergic reaction.

Before or as soon as possible after working with TDI, affected workers should undergo a complete work and medical history, lung function tests, chest X-rays, and blood tests. This is especially important for those workers who have a history of upper respiratory/lung allergies, previously weakened lungs, and lung or throat problems at the time of exposure.